Cold working

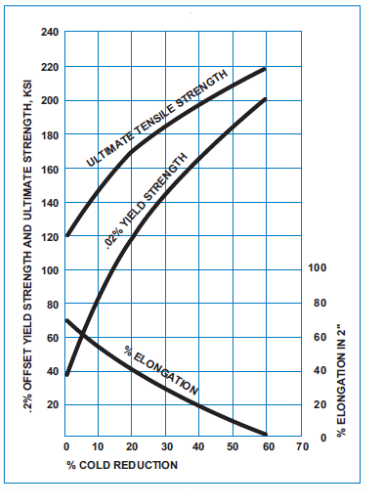

Cold working results in increased metal strength and decreased elongation.

Amount of the changes increase as the amount of cold working increases.

For stainless steel, cold working for the purpose of increasing strength is used primarily with austenitic alloys.

For cold-rolled sheet and strip temper designations indicate the amount of cold working performed on the metal. The temper designations are ¼ hard, ½ hard, ¾ hard, and full hard, in order of increasing amount of cold rolling.

For bar, the designation Condition B refers to bar in the cold-drawn condition

Cold-Rolled Tempers for 301 sheet and strip

| Temper | Minimum tensile strength, ksi (MPa) | Minimum yield strength, ksi (MPa) | Minimum elongation, % |

| Annealed | 75 (515) | 30 (205) | 40 |

| ¼ hard | 125 (860) | 75 (515) | 25 |

| ½ hard | 150 (1035) | 110 (760) | 18 |

| ¾ hard | 175 (1210) | 135 (930) | 12 |

| Full hard | 185 (1275) | 140 (965) | 9 |